TIANZHAO Milling Cutter

Made in China

Manufacturer of quality hardware tools since 2005.

TianZhao helps you leap from the concept stage to reality.

Find our full range of customized solutions to take your business to the next level.

Discover Our Product Lines

We investigate the real needs of end users and offer OEM services. Choose from our product range and contact Contact Us for a free quote. Flexible minimum order quantities are available.

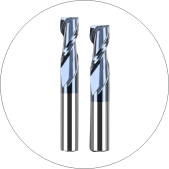

The end mill is the most used

milling cutter on CNC machine tools. The end mill has cutting tools on the cylindrical surface and end face, and they can cut simultaneously or separately. It is mainly used for plane milling, recess milling, step surface

milling and profiling milling.

Saw blade is the collective name of thin circular cutter used to cut solid materials. Saw blades can be divided into: diamond saw blades, high-speed steel saw blades, carbide saw blades.

The drill is a rotating type of cutting tool, or one with multiple cutting edges. When drilling, the drill is pressurized to approach the workpiece, and the pressure and speed force the drill through the workpiece, leaving a round hole.

Abrasive head is a general term for a small grinding tool with a handle, which is used in electric grinders, crane grinders and hand drills. There are many kinds of grinding heads, such as ceramic, rubber, diamond and abrasive heads.

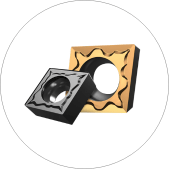

CNC inserts are a general term for indexable turning inserts, which are the mainstream products in modern metal cutting applications. It is mainly used in metal turning, milling, grooving, thread turning and other fields.

Taps are tools for processing internal threads and are divided into spiral groove taps, tapered taps, straight groove taps and pipe thread taps.

Customization Options At Your Fingertips

Browse our library of customization options. We understand how our customers bring solutions to the table by providing endless customization settings.

We offer endless possibilities to help you accomplish your goals. With the support of our industry experts, your brilliant ideas will never be compromised.

Material

Material

The tool materials commonly used in current production are mostly HSS and carbide. Carbon tool steel and tool steel are only used for manual or low cutting speed tools due to poor heat resistance.

Size

Size

The main consideration for the end mill should be the requirements of the workpiece size and to ensure that the required power of the tool is within the rated power of the machine tool.

Coating

Coating

Carbide tool coatings have the effect of increasing wear resistance, improving oxidation resistance, reducing friction, improving metal fatigue resistance, and increasing thermal shock resistance.

Streamlined Collaboration Process

Customers Provide Their Own Drawings.

We can provide customers with a choice of material suppliers, such as Jiangxi Tungsten Holding Group Co.

We can finish proofing within 3-5 days and deliver within 30 days.

The Customer Does Not Have Drawings.

Our experts can give you a professional selection of tools based on the name of the equipment you provide.

Then

We only provide cost-effective products, and the price and quality of raw materials will be strictly controlled. One is to ensure the quality, and the other is to reduce the cost of customers.

You can ask all the questions you want to know or solve, and you can get the service of our experts for free, so as to get reasonable advice and usage.

Processing Tools For Various Industries

Our engineers are constantly innovating and expanding our products to meet the ever-changing needs of material compositions. By partnering with state-owned material producers and industrial manufacturers to manufacture a comprehensive product line, TianZhao has been a leading supplier for over a century .

3C

→

Cars

→

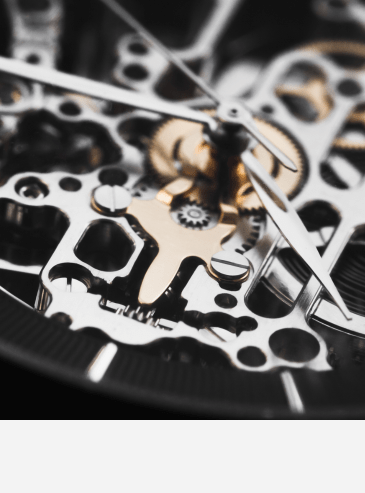

Watches

→

Aerospace

→

Medical

→

Railroad

→

Ships

→

Weapons

→

Eyeglasses

→

Energy

→

Can't Find The Ideal Tool For Your Industry

We offer custom solutions for all our customers.

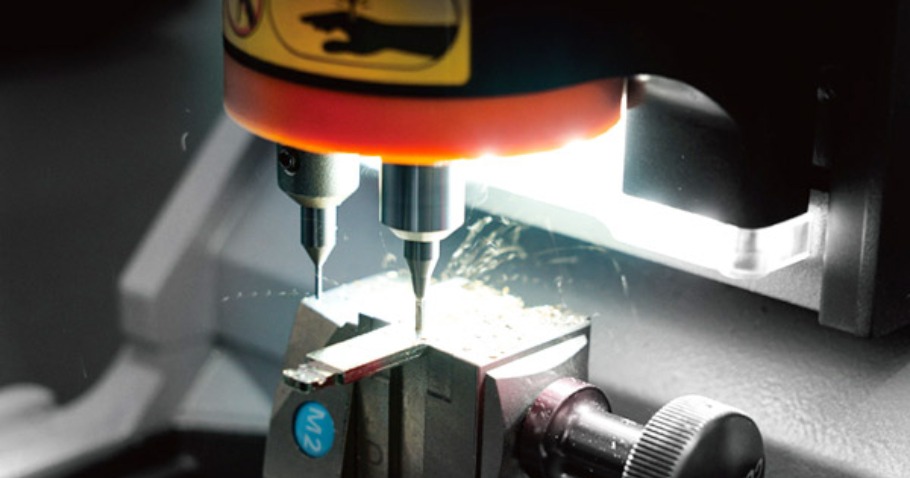

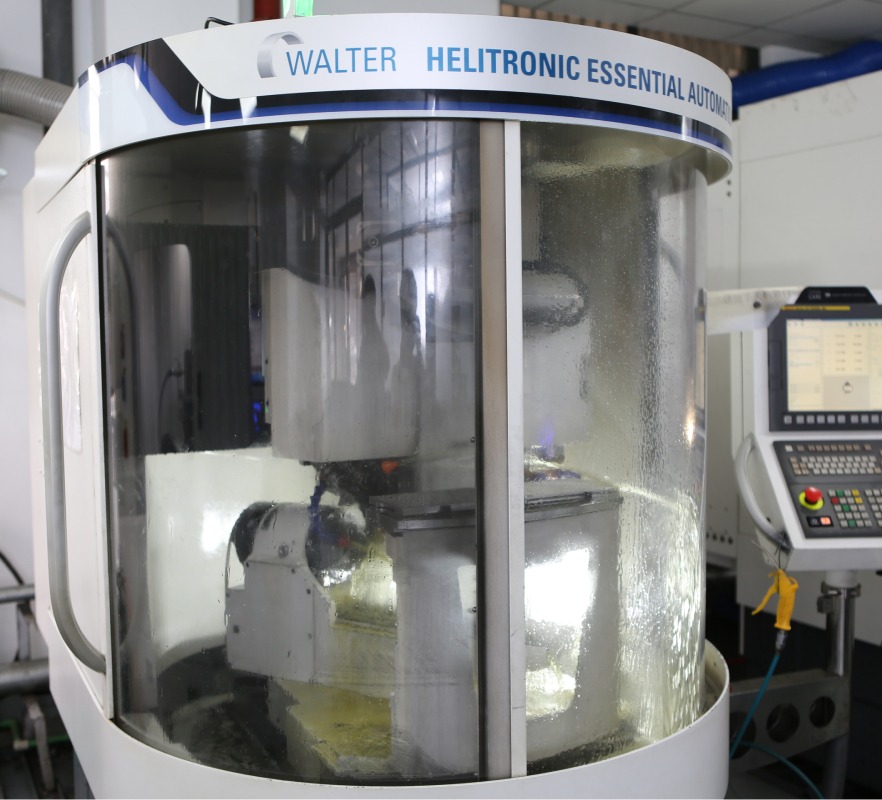

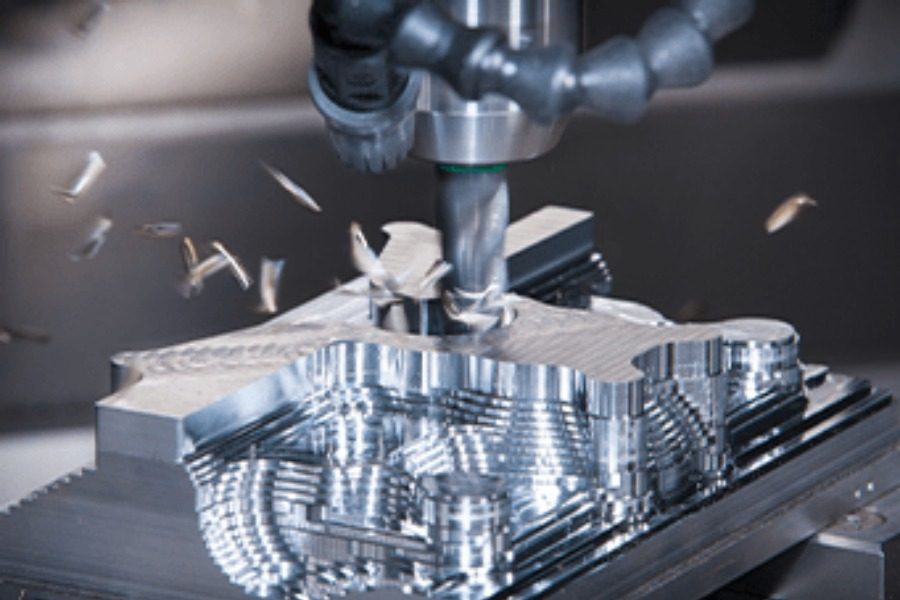

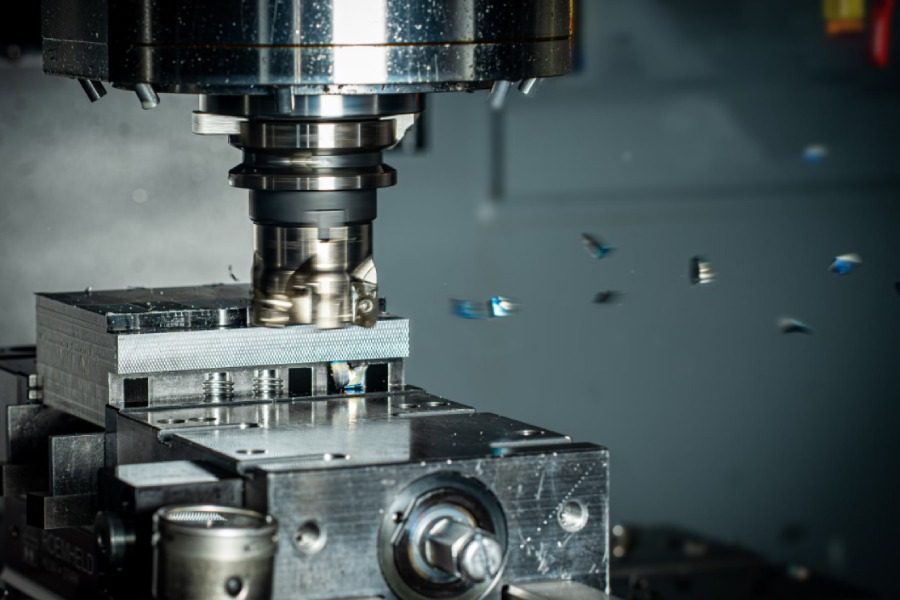

Combining Mechanical Precision And Handcrafted Elegance

Putting our passion and soul into each of our manufacturing tools requires the use of cutting edge machinery to machine each tool. These tools are finely polished by our experienced craftsmen. Combining superb hand polishing with automated technology, we can provide the right solution for your industry.

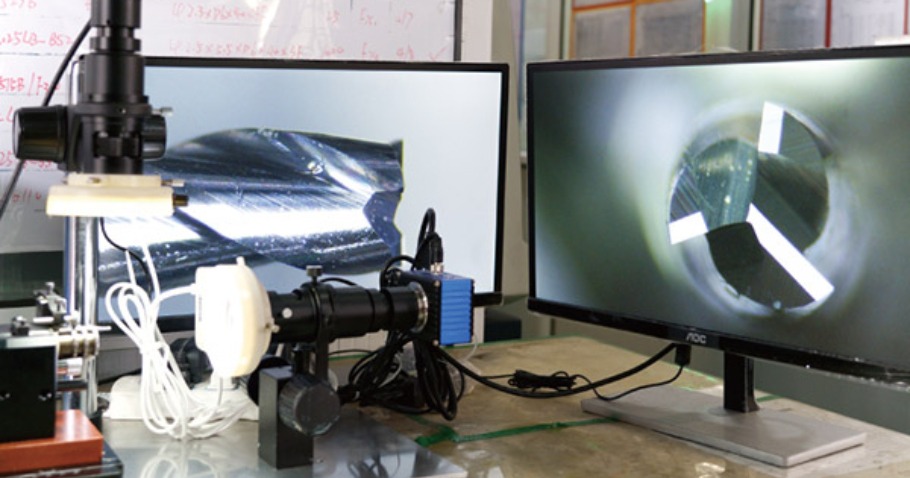

Production Tools. No Shortcuts

Crafted Hardware Tools

At Tianzhao, every finished tool is the result of a team effort.In order to improve the quality of each tool’s work, we pay special attention to every process involved in making a tool. From material to size, from grinding to polishing, we do not allow any mistakes.There are no shortcuts to sharp and tough tools, only craftsmanship.

01

Mold process

02

Alloy process

03

Deep Processing

Process

04

Coating process

01

Mold process

02

Alloy process

03

Deep Processing

Process

04

Coating process

Demanding Tool Manufacturing And Quality Control Processes

Tianzhao’s production is centered on quality and has its own quality control process every step of the way. We start by running our materials, sizes, coatings and wood components through a rigorous selection process and only source from well-known brands or suppliers.

Understanding Tianzhao By The Numbers

Our Success Stories

Application of Ti press Zhao faces milling cutter in machining automotive engine cylinder head.

Success stories of cutting technology for aerospace parts machining.

Tianzhao Dental Solutions.

Be One Of The Many Cases

First-class Hardware Tools Base Camp

We’re the factory you’ve been looking for.

Tianzhao has been specializing in providing hardware tool OEM services for over 17 years. With our modern production line, we offer a full range of processed tools for wholesalers and brand owners.

We work hard with an unwavering commitment to be the perfect extension of your business through your order from R&D and manufacturing to comprehensive service.

What Makes Us Different

- Timeline Control

We know your sense of urgency. Outstanding teamwork and excellent schedule control really allow us to run urgent and small batch projects.

- Budget Control

Our PCMs are experts at finding quality materials and efficient techniques to meet your budget. We also offer exclusive budget plans.

- Industry Leading Experience

Tianzhao has served Fortune 500 and elite teams. Their relatively high demands and industry-leading knowledge keep us moving forward.

- The Experts Behind You

Tianzhao employees are knowledgeable and self-motivated, giving us a collegial work environment. These are the keys to our effective collaboration.

From The Blog

How to Choose The Right End Mill?

Choosing the right end mill could be a really hard thing…

6 of the Best Cutting Tool Manufacturers: Comprehensive Guide

The milling industry involves a versatile machining process…

How to choose CNC cutting tools?

CNC cutting tools are nothing new. Humans have been creating and refining tools from the…

What Do Customers Say?

Lencon

> > >

“Through cooperation, TIANZHAO in product quality, duration, cost and other aspects of effective control left us a professional, cost-effective, efficient and good impression. “

June 22, 2021

Kernan

> > >

“We received the first order of end mill here. Those are in good condition & Cutting area covered with a protective cover in order to prevent damage. That is very good.”

August 20, 2021

Danis

> > >

“We have already tested 10 mm end for Stainless steel with good yield & Test goingon for 3 mm end mill for an aluminum one. Other end mills to be tested & I have confidence that it will bring a good result.”

October 12, 2021

More Benefits Of Working With Us

Short Delivery Time

Thanks to our round-the-clock automated facilities, we can deliver your order in almost 7-15 days.

Quality Assurance

Our quality manufacturing team follows ISO guidelines and 6S management principles to process your order with maximum efficiency.

Competitive Prices

By controlling the development and production process, we can confidently offer you competitive prices.

Full Support And Service

From pre-sales to manufacturing and after-sales, we provide timely support and service to meet your every need.

Short Delivery Time

Thanks to our round-the-clock automated facilities, we can deliver your order in almost 7-15 days.

Competitive Prices

By controlling the development and

production process, we can confidently offer you competitive prices.

Quality Assurance

Our quality manufacturing team follows

ISO guidelines and 6S management principles to process your order withmaximum efficiency.

Full Support And Service

From pre-sales to manufacturing and

after-sales, we provide timely support

and service to meet your every need.

That's enough about us. Let's talk about your tools project now.

At Tianzhao, it’s easy to find the tools you’re thinking of.

- Professional feedback within 8 hours

- The ability to rely completely

- Best price for you

- Fast design in 12 days

- Fast delivery within 35-40 days

Contact Our Tool Experts

*We respect your confidentiality and all information is protected.