Instant quotes for 1-1,000 units

Flexible lead time

options

High-quality raw

materials

Absolute

accuracy

Multiple certificate guarantees

Our Products

With specialized geometries to enhance tool results, TIANZHAO solid carbide, high performance miniature end mills extend tool life, improve finish, and decrease cycle times.

steel ball cutter

alloy drill

alloy saw blade

double taper knife

Applications Of Our Products

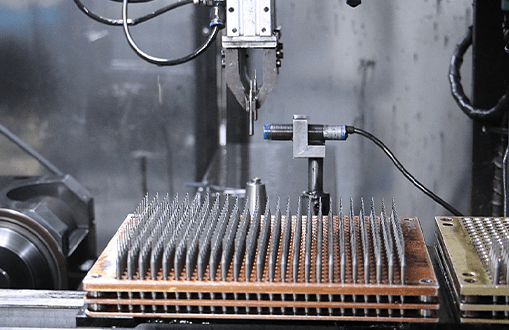

Electronic product field

The plunge milling method is mainly used in CNC machine tools with the characteristics of high speed, high efficiency and high degree of automation. Generally, it should include general tools, general connection tool holders and a small number of special tool holders.

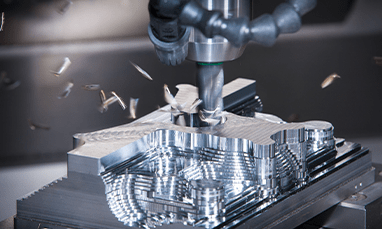

Mold field

Plunge milling is ideal for roughing mold cavities and is recommended for efficient machining of aerospace components. One of the special uses is the plunge milling of turbine blades on special machines.

Medical Dentistry

Medical devices, such as implant products and prosthetics, play an important role in successful surgical procedures, helping surgeons achieve the best possible medical outcomes. The use of knives in medical device manufacturing is diverse and extensive.

We Provide Customized Services

√ We can provide customers with choice of material suppliers, such as Jiangxi Tungsten Holding Group Co., Sumitomo Group.

√ We can complete the proofing within 3-5 days and deliver within *** days.

√ We only provide cost-effective products, and the price and quality of raw materials will be strictly controlled. One is to ensure the quality, and the other is to reduce the cost of customers.

√ You can ask all the questions you want to know or solve, and you can get the services of our experts for free, so as to get reasonable suggestions and usage methods.

√ Our experts can give you professional tool options according to the equipment name you provide.

√ We only provide cost-effective products, and the price and quality of raw materials will be strictly controlled. One is to ensure the quality, and the other is to reduce the cost of customers.

√ You can ask all the questions you want to know or solve, and you can get the services of our experts for free, so as to get reasonable suggestions and usage methods.

Ordering From Us

Here is a simple process on how to order our products. We help our customers produce standard or custom

milling tools for multiple industries and sectors: automotive, electronics, hardware startups,

industrial automation, machinery, manufacturing, medical devices.

Contact us for a quote.

Determine whether the product required by the customer is customized.

Assembly line production.

Production completed, packaged and mailed.

Customer receipt.

Why Choose Us

Reason

Confirmation of materials

Packaging and labeling

Transportation and logistics

After-sales guidance

FAQ's

Yes, we are factory for more than 15 years in CNC tools.

No matter you order standard products or non-standard products, we will arrange delivery within 3-5 days.

If your order is big enough, we will provide you with free sample.

T/T 30% deposit, 70% balance against B/L copy or 100% irrevocable LC at sight. More payment terms are available(Paypal, Xtransfer).

We use the Walter which imported from Germany and Anca Fx5 Linear.

Of course, but it is better to wait until the epidemic subsides. Now we support using ZOOM for online factory inspection.

Yes, we do. We have laser machine lasering your logo and tool specification on the body of tools. Also, we can print customized on plastic boxes.

Usually delivery time is 2~3 days after receiving the advance payment. For the customized product, 7-10 days after receiving the advance payment.