Table of Contents

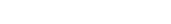

Milling cutter tools are an essential part of any manufacturing or production process. They are used to cut, shape, and mill materials into the desired forms.

Milling cutter tools are also an essential part of your economy. By increasing the life of milling cutter tools, we can improve productivity and generate more revenue. However, there is more to it than that. Ripping and regrinding milling cutter tools can be profitable if done correctly.

This blog post will explore the relationship between tool life and productivity and discuss how re-tipping and regrinding can help your business thrive!

This blog contains:

1. The most important points about the life and function of the milling cutter that customers are concerned about and the relationship between the life of tools and customers’ economic efficiency.

2. Illustration of the relationship between the life of milling cutters, drills, and customers’ economic efficiency to emphasize that milling cutters with longer lifespans and higher productivity can help you save more money.

3. The meaning and importance of life and productivity of milling cutter tools to profit and manufacturing process or other business activities.

4. How we manufacture tools with longer life and more productivity/Perfect milling cutters manufacturing process.

5. What we can provide for our customers to prolong the life of our tools and innovative ways to make our tools more productive.

6. Emphasis on our after-sales service and warranty.

The most important points about the life and function of the milling cutter and the relationship between the life of tools and customers’ economic efficiency:

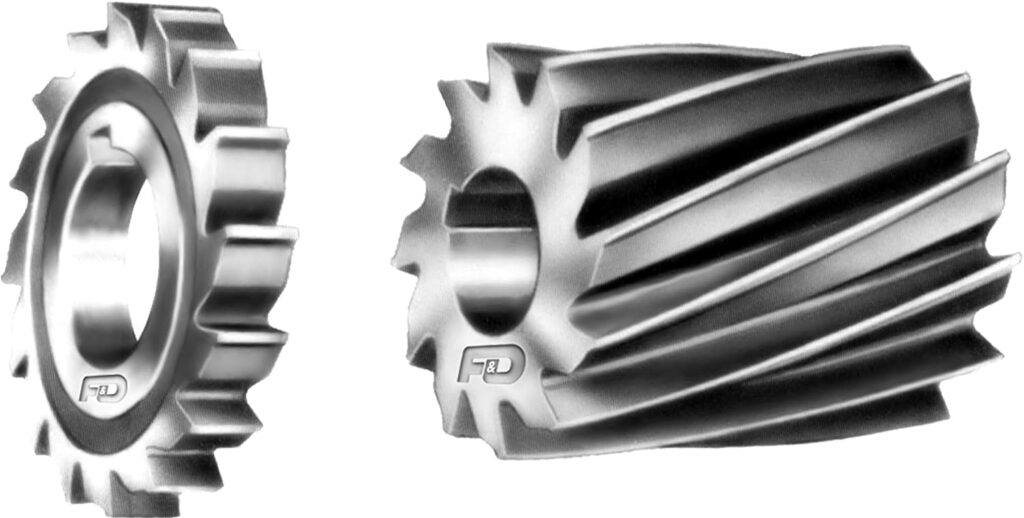

A milling cutter is a cutting tool used in milling operations. It has sharp teeth that cut material as the milling cutter rotates. The milling cutter tool life is determined by many factors, such as:

– Material hardness

– Cutting speed

– Depth of cut

– Feed rate

– Tool geometry

– Coatings

Material hardness

Material hardness is the most important factor in milling cutter tool life. The harder the material, the shorter the milling cutter tool life.

Cutting speed

Cutting speed is the second most important factor in milling cutter tool life. The faster the cutting speed, the shorter the milling cutter tool life.

Depth of cut

Depth of cut is the third most important factor in milling cutter tool life. The deeper the depth of cut, the shorter the milling cutter tool life.

Feed rate

Feed rate is the fourth most important factor in milling cutter tool life. The higher the feed rate, the shorter the milling cutter tool life.

Tool geometry

Tool geometry is the fifth most important factor in milling cutter tool life. The sharper the tool, the shorter the milling cutter tool life.

Coatings

Coatings are the sixth most important factor in milling cutter tool life. The thicker the coatings, the shorter the milling cutter tool life.

All of these factors are important to consider when determining milling cutter tool life. By increasing the life of milling cutter tools, we can improve productivity and generate more revenue. However, there is more to it than that.

In other words, the longer the milling cutter lasts, the more money the customer saves. This is why it is important to choose a high-quality milling cutter that is designed for the specific application.

The life spans of milling cutters can affect the use procession of manufacturing or other business activities and the economy as a whole.

When milling cutter tools have a long life, it means that customers can use them for a longer period.

This results in increased productivity and less downtime. In addition, it also means that the customer saves money on replacement milling cutter tools.

Illustration of the relationship between the life of milling cutters, drills, and customers’ economic efficiency

The longer the milling cutter tool life, the more money customers save. Milling cutters with longer lifespans are more productive and can help you save more money.

As mentioned before, the life of milling cutter tools has a direct relationship with customers’ economic efficiency. The longer the milling cutter lasts, the more money the customer saves.

This is because they will not have to replace the milling cutter as often. In addition, they will also experience less downtime, which means they can be more productive.

Milling cutters with longer lifespans and higher productivity can help you save more money!

Drills are another type of cutting tool that is used in milling operations. like milling cutters, drills also have a direct relationship with customers’ economic efficiency.

The longer the drill lasts, the more money the customer saves. This is because they will not have to replace the drill as often. In addition, they will also experience less downtime, which means they can be more productive.

In conclusion, milling cutters and drills with longer lifespans are more economical and can help customers save money.

The meaning and importance of life and productivity of milling cutter tools to profit and manufacturing process or other business activities

The milling cutter tool life has a direct relationship with customers’ economic efficiency. The longer the milling cutter lasts, the more money the customer saves.

This is because they will not have to replace the milling cutter as often. In addition, they will also experience less downtime, which means they can be more productive.

The milling cutter tool life also has a direct relationship with profit. The longer the milling cutter lasts, the more money the company makes. This is because companies save on replacement milling cutters and experience less downtime.

In conclusion, milling cutters with longer lifespans are more profitable and can help companies save money.

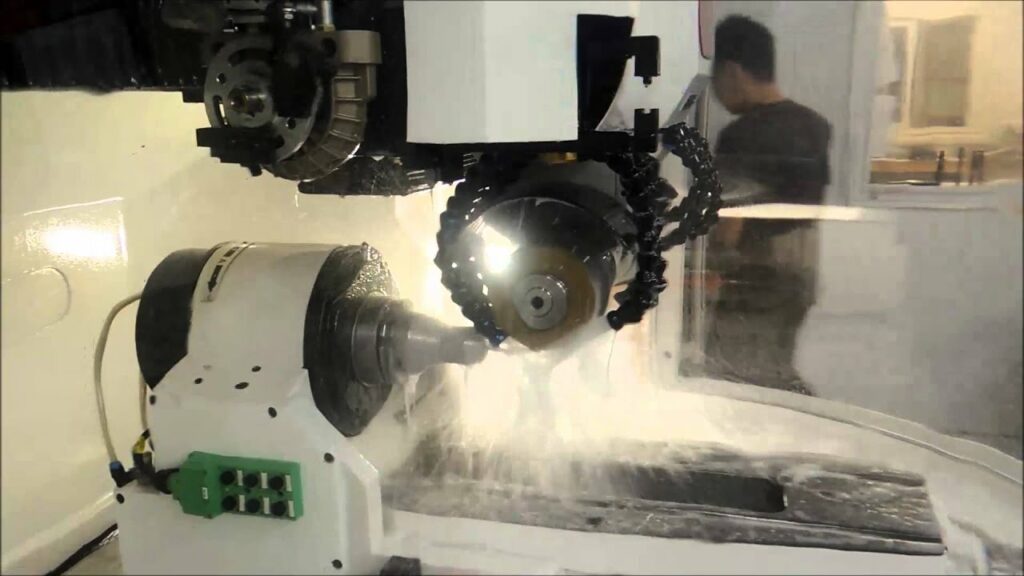

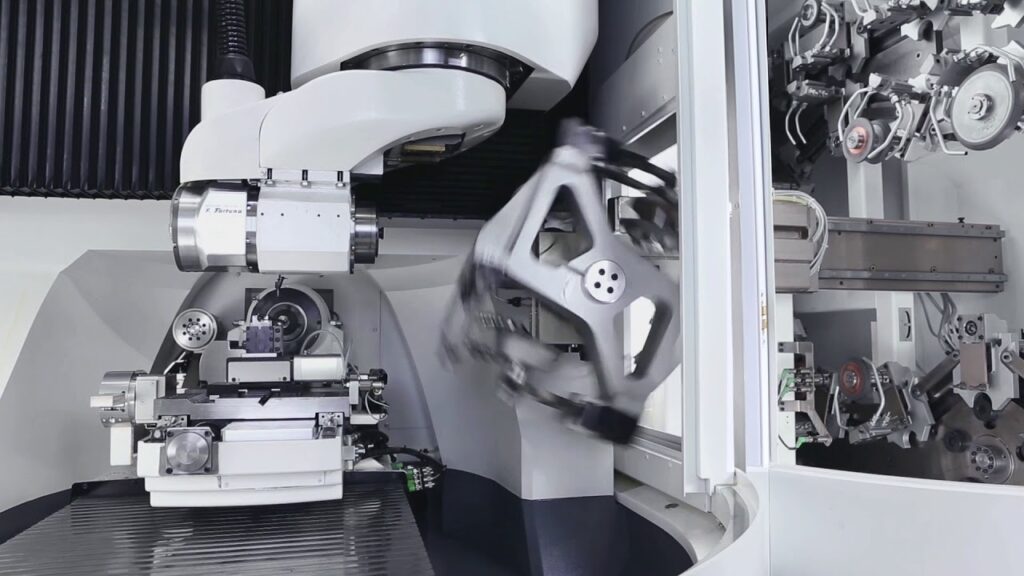

How we manufacture tools with longer life and more productivity/ Perfect milling cutters manufacturing process

We manufacture milling cutters with longer life and more productivity by using a variety of methods.

One method is by using coatings. Coatings are the sixth most important factor in milling cutter tool life. The thicker the coatings, the shorter the milling cutter tool life.

Another method is by choosing a high-quality milling cutter material that is designed for the specific application.

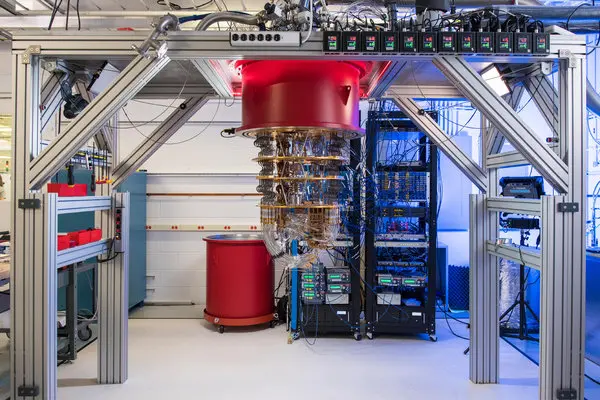

This will help to increase the lifespan of the milling cutter. Our materials are sourced from Kenna, Googling, and Sandvik, which can guarantee the quality of milling cutters.

Also, we place great emphasis on the heat treatment process of milling cutters. The heat treatment process is critical to the lifespan of milling cutters. Our milling cutters are heat-treated using a vacuum furnace, which can help to extend the lifespan of the milling cutter by up to 30%.

Finally, we use the best quality testing equipment–SAACKE and VALTER. This helps us to ensure that our milling cutters are of the highest quality and will last long. Both testing pieces of equipment that specialize in millingents give us the best inspection results.

What we can provide for our customers to prolong the life of our tools and innovative ways to make our tools more productive

We can provide our customers with milling cutters that have a longer lifespan and are more productive by using a variety of methods.

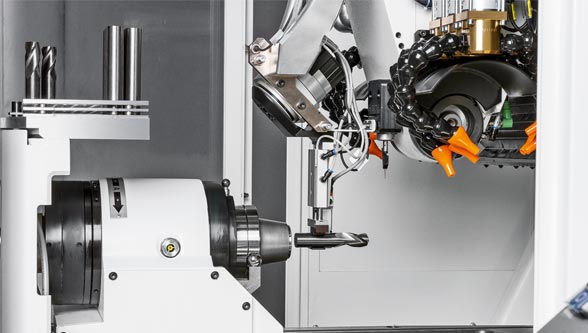

Retipping and regrinding milling cutter tools is one way to extend their life and improve productivity.

Retipping

Retipping is the process of replacing the worn-out cutting teeth on a milling cutter tool. This is a cost-effective way to prolong the life of a milling cutter tool.

Regrinding

Regrinding is the process of sharpening the cutting teeth on a milling cutter tool. This can also help to extend the life of the milling cutter tool and improve its productivity.

Retipping and regrinding can give you back new-tool performance at a fraction of the new-tool cost. As long as the tool body remains in good condition, we can rehabilitate it through an indefinite number of retipping cycles.

That gives you a big boost in the tool-economy department and turnarounds that are up to several days later.

Before we begin a regrind or retip process, we inspect every tool. If the tool body has taken a hit during a crash, the collision can destroy the pockets that should contain PCD or carbide.

If that’s the case, we either return the tool to the customer so they can recycle it or do so ourselves at their request.

If the tool shaft no longer runs true and will cause run out, we’ll notify you immediately. Once we’re certain that we can return the tool to its original geometry, we rehabilitate it.

Of course, that “simple” retipping process isn’t as simple as replacing a light bulb, or you wouldn’t need specialists like us to do it right.

Just as you won’t find your purpose-built tools at a big-box home-improvement store, you won’t find a toolmaking company like TIZNZHAO cutter that also specializes in regrinds and retips.

Most firms won’t regrind or retip tools they didn’t make, but we will. When you entrust your tools to us for retipping, you apply our proprietary brazing process for a stronger, better-performing tool that other options can’t produce.

You get the ideal combination from TIANZHAO cutter: unique new tools plus top-quality regrinds and tips. We help you maximize tool life, workpiece quality, and production profitability in every way we can.

Beyond our toolmaking expertise and tool rehab skill, we’re here to solve your problems, including some – such as lengthy shipping time – that you may have thought you couldn’t avoid. We specialize in the problem-solving business.

Inspection

Measuring, and shipping are all part of the milling cutter tool-rehabilitation process.

After we finish a milling cutter tool, we inspect it to see what work needs to be done. If the milling cutter is damaged beyond repair, we’ll recycle it or return it to you at your request. If the milling cutter is in good condition, we’ll begin the retipping or regrinding process.

We measure the milling cutter tool to make sure that it meets our high standards for quality. Once we’re finished measuring the milling cutter tool, we’ll ship it back to you. You can expect your milling cutter tool to be returned within a few days.

Emphasis on our after-sales service and warranty

We offer a full warranty for all of our products. We also have an after-sales service team to help you with any questions or problems you may have.

Our after-sales service team is available 24/365. We will do whatever it takes to make sure you are satisfied with our products and services.

If you have any questions, please don’t hesitate to contact us. We would be more than happy to help you in any way we can.